At Chembotix, we are developing robotic solutions to streamline labor-intensive chemical R&D. Our technologies improve the efficiency of multi-stage reactions, making chemical development faster, safer, and more cost-effective. Whether you're in pharmaceuticals, energy systems, or other industries, we offer the innovative solutions you need to advance the future of chemistry in your field. Our proprietary lab bench-sized robot automates the entire process, from accepting chemical ingredients in sealed containers to dispensing them into reactors, performing reactions, conducting chromatography on the resulting mixtures, and analyzing the results with an onboard spectroscopy unit.

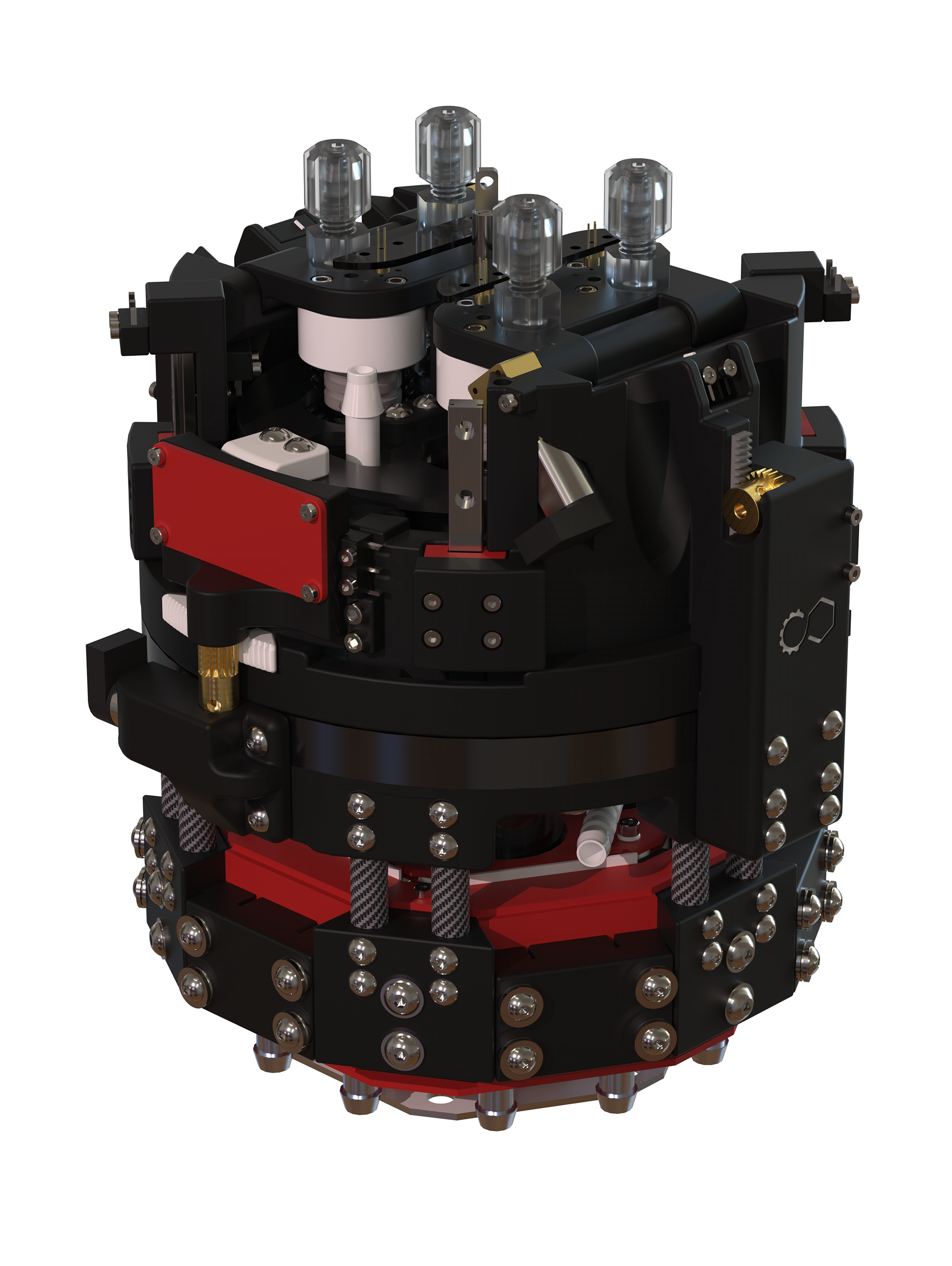

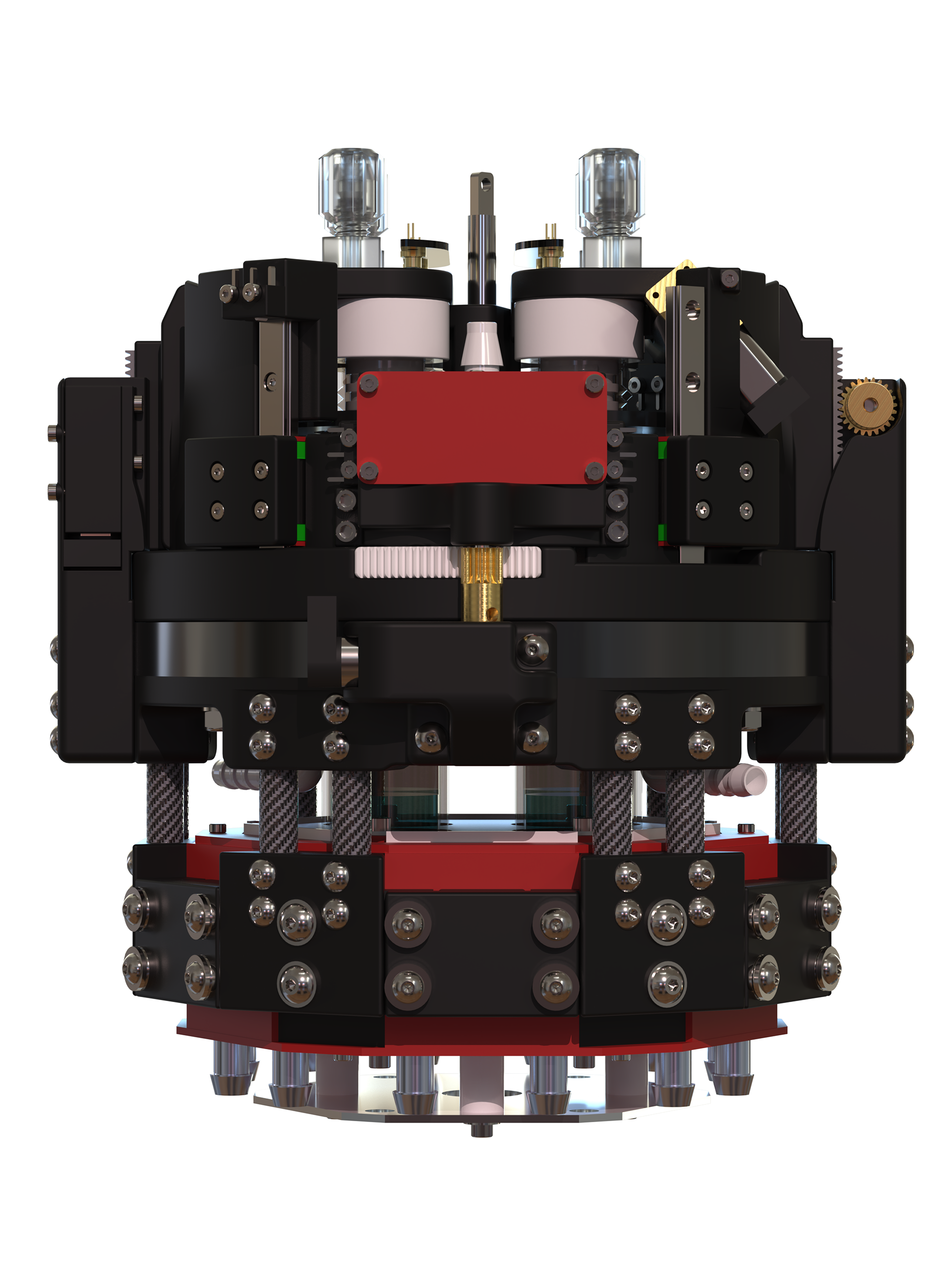

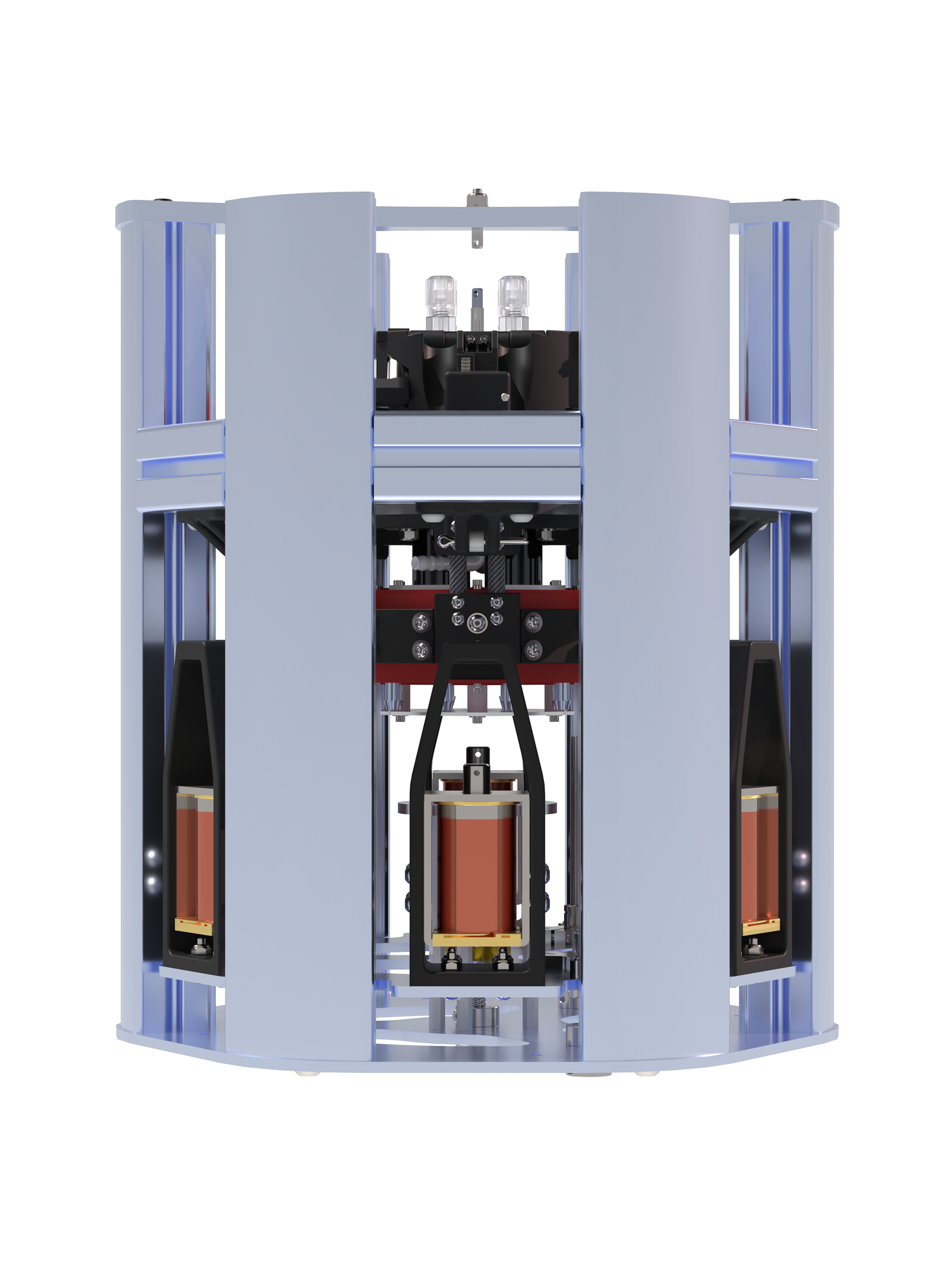

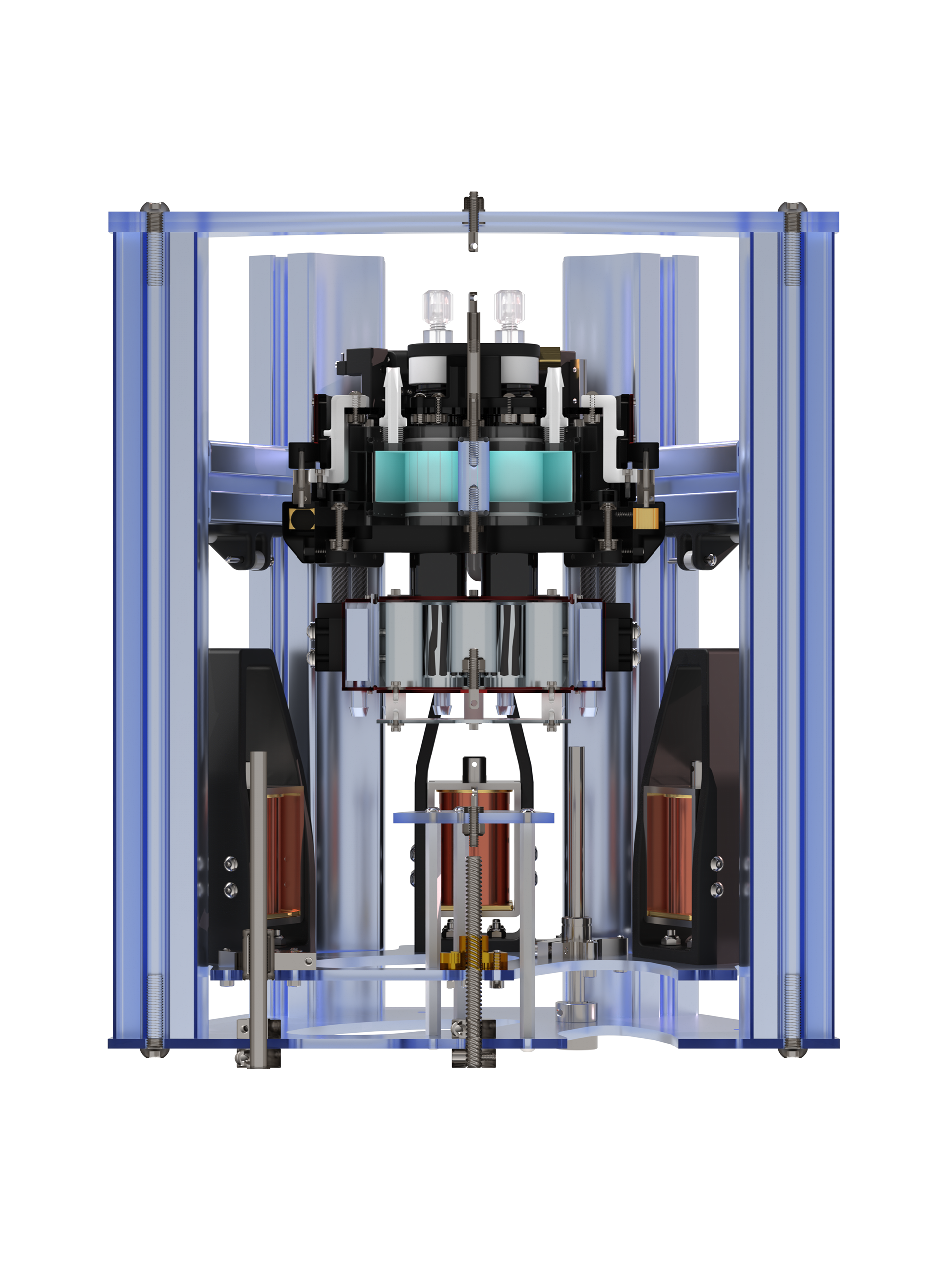

Chemical Reactor

The Chembotix chemical reactor is a groundbreaking design, offering continuously adjustable frequency and amplitude mixing. This innovation allows chemicals to be mixed in real-time as they are added. This functionality is achieved through six solenoids fixed within the main frame, surrounding the reactor's core. By sequentially actuating the solenoids at adjustable amplitudes and frequencies, the spring-suspended core is moved in a circular motion.

The reactor’s core features six Peltier pads and liquid temperature control blocks, providing active cooling and heating of the chemical mixtures. Carbon fiber rods insulate the upper section from the lower temperature-controlled section. The upper section houses an internal copper reflux condenser mounted to the inner side of the four vial lids, along with an external reflux condenser that encapsulates the upper half of the vials.

The vial lids are motor-driven, moving vertically before rotating outwards to accommodate the internal condensers. A ring-lock mechanism securely fastens the vial lids during operation at above-atmospheric pressures. Additionally, the internal vial pressure can be adjusted using a hose fitting mounted on the top of the lid, enabling precise control over certain chemical reactions.

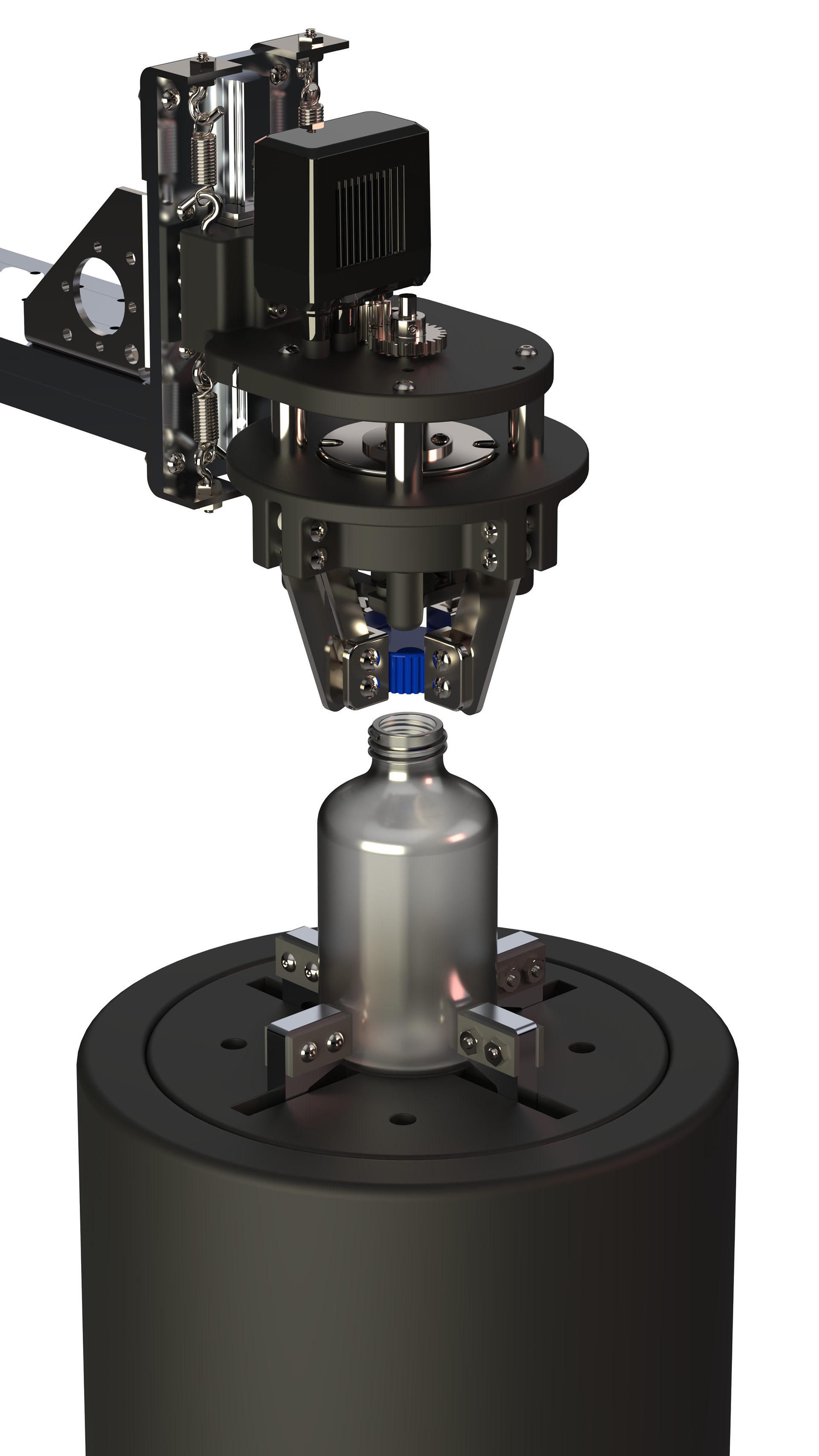

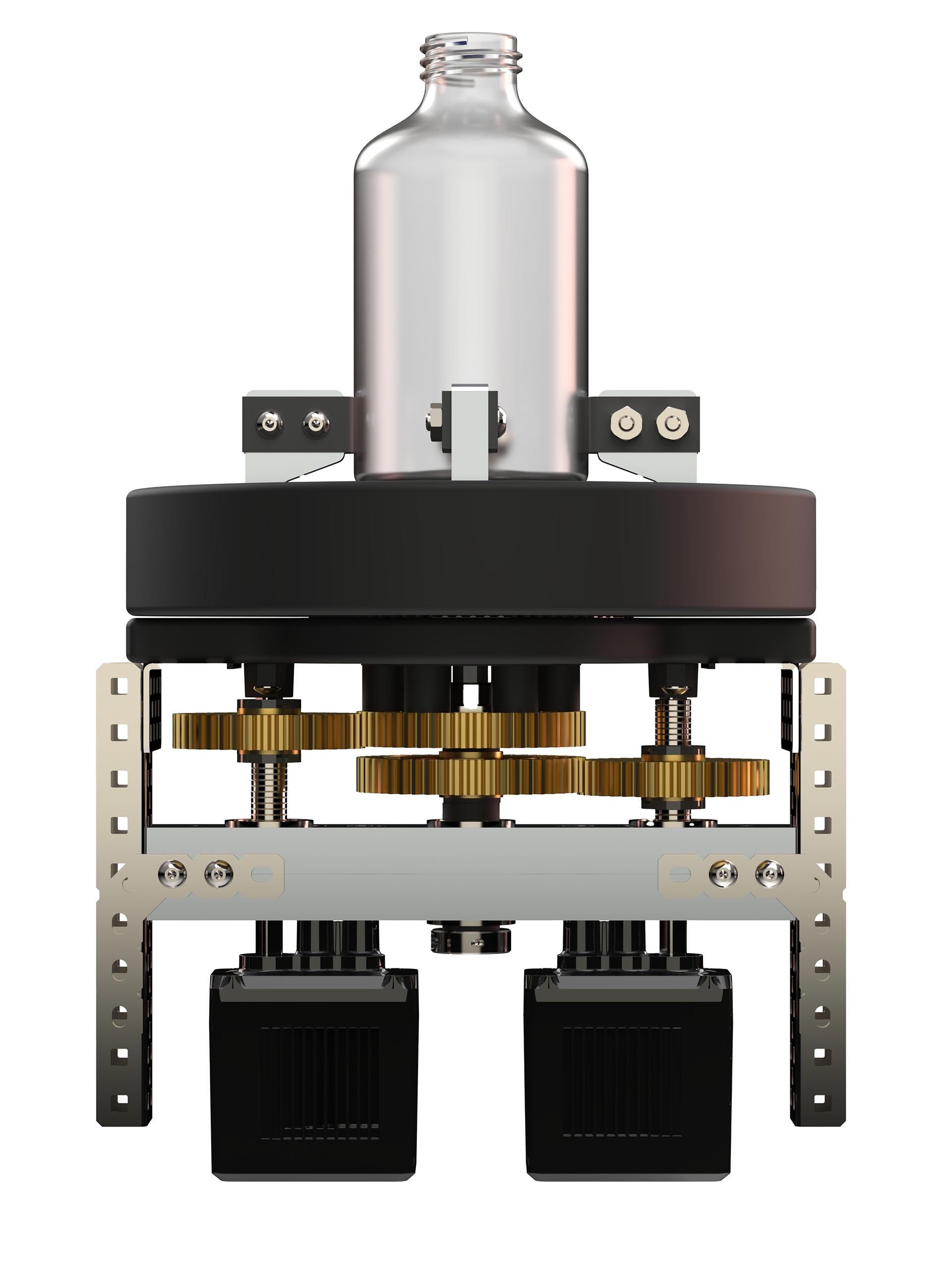

Robotic Bottle Opener

The Chembotix robotic bottle opener is designed to accommodate a wide range of bottle sizes and lid features, including safety seals, within our robotic organic chemistry system. This innovation enables users to keep chemicals in their original packaging, eliminating the need to transfer them to proprietary containers. The bottle gripper uses four arms to securely hold the bottle, while the upper gantry arm is positioned to grip the lid. The gantry arm loads the spring to accommodate any thread pitch, and the bottle gripper then rotates to either remove or secure the lid in place.

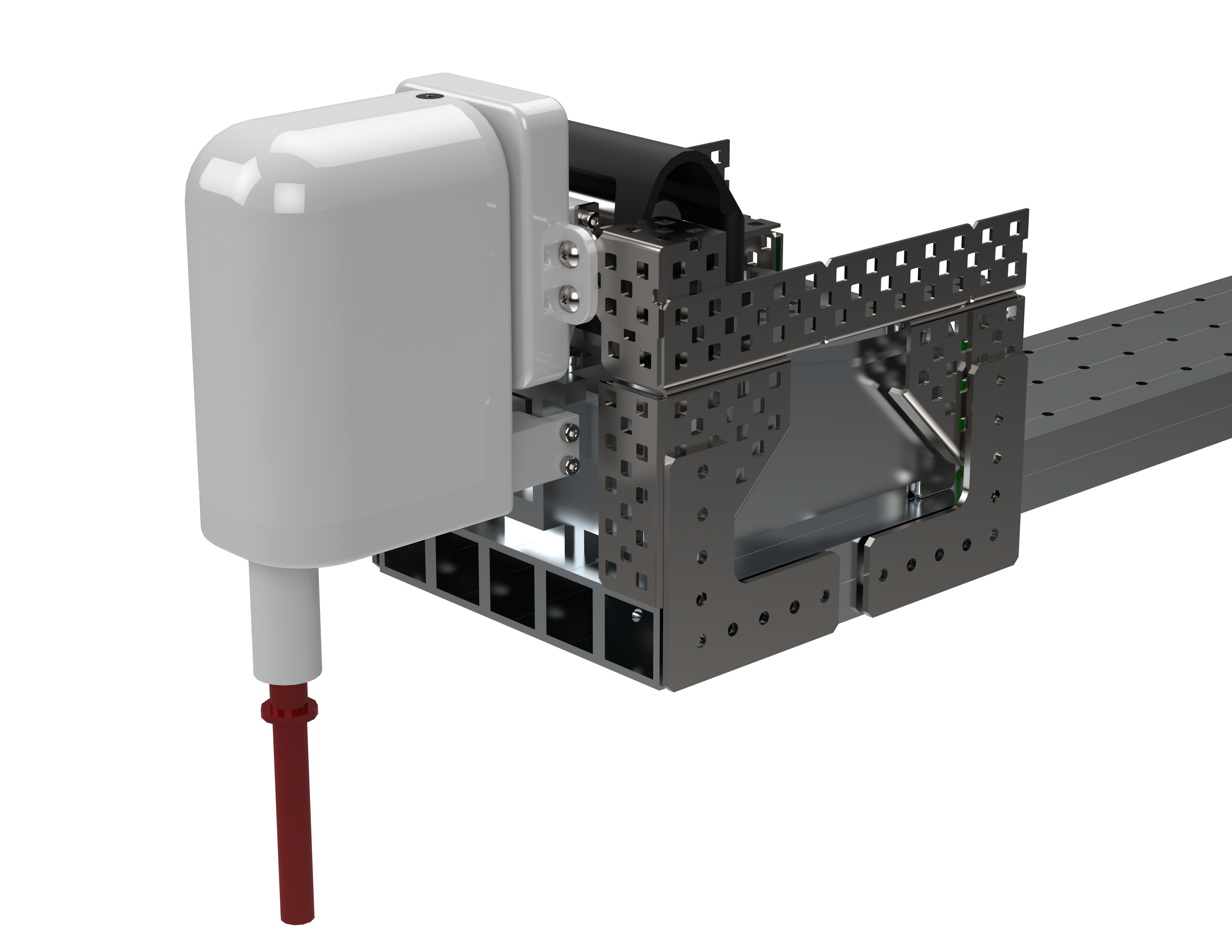

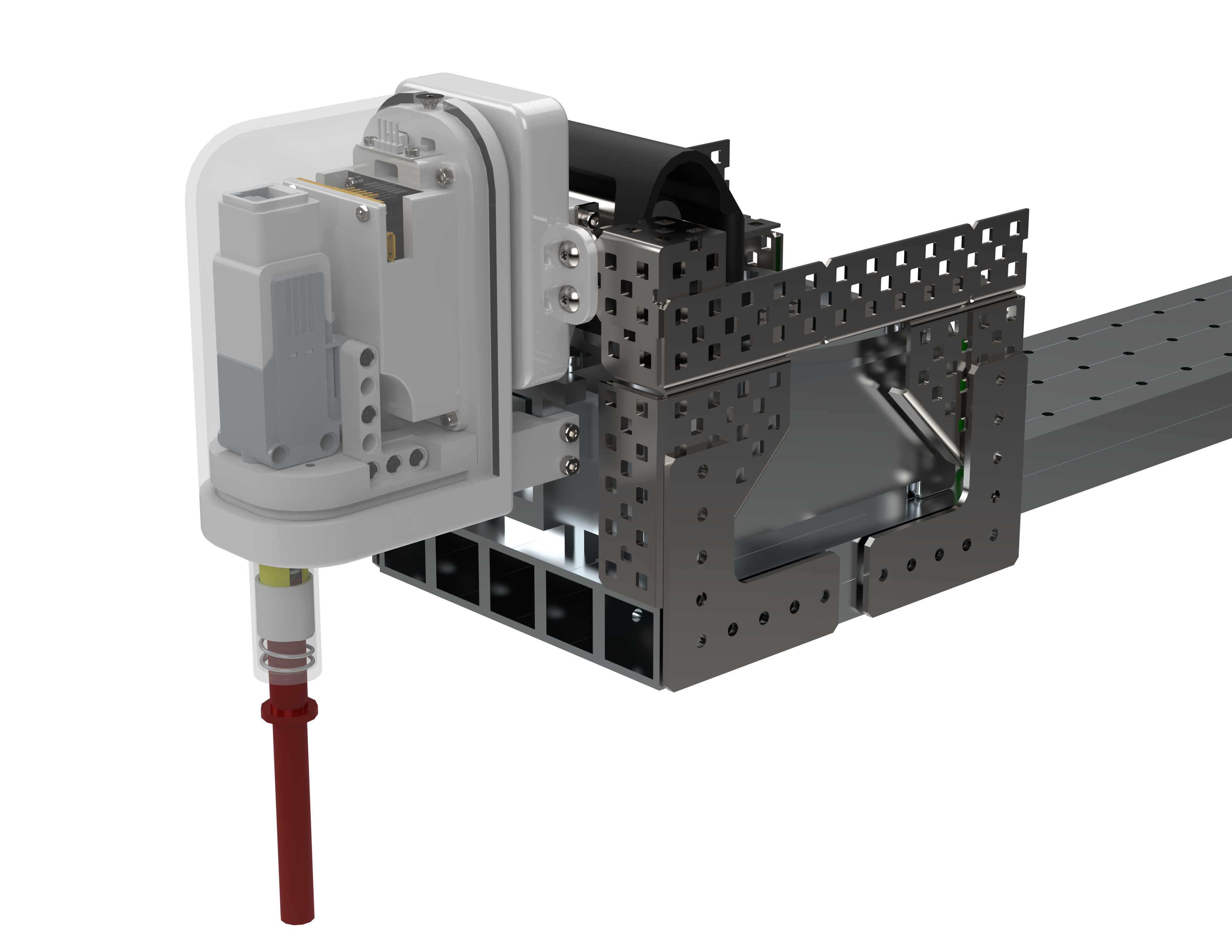

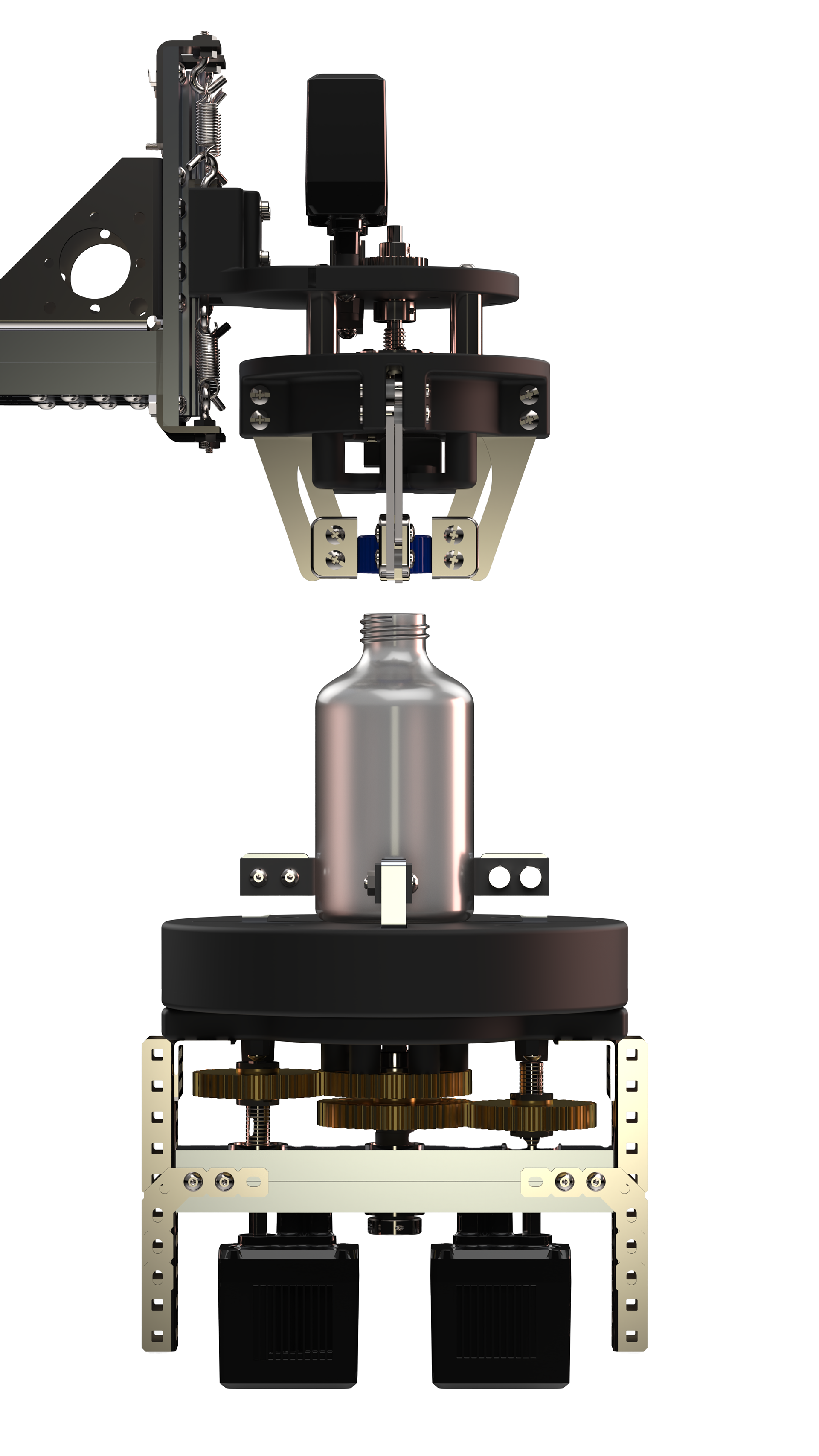

Chemical Dispensing Module

The Chemical Dispensing Module (CDM) is mounted on the opposite side of the gantry arm from the bottle lid gripper. It features a scale, interchangeable modules, and a wireless charging/communications unit. Shown below is the powder dispensing module, with other versions including a liquid pipette module and a pellet pickup module. Chemical dispensing is precisely monitored using the scale. The powder module includes an auger tip that can be detached via a spring-loaded click mechanism. Wireless charging powers the batteries onboard each module, eliminating the risk of weight measurement errors from wires bridging into the weight-sensitive area.